Characteristics Excellent crack resistance, thermal c...

- Home

- About Us

- Products

- Xrun Epoxy Resin Additives and Auxiliary Materials

- Epoxy insulating glue

- Epoxy Resin Systems For HV Products

- Epoxy Systems for Dry-Type Transformers

- Epoxy Resin System for MV & HV Insulation Parts with APG Process

- Flame-Retardant Epoxy Resin Systems

- Epoxy Resin Systems for Electric Insulation of High Thermal Conductivity

- Epoxy Resin Systems Curing at Ambient Temperature

- Epoxy Resin Systems for Outdoor Electrical Insulation

- Epoxy Resin Systems for Electric Composite

- Epoxy Systems for CT/VT

- Flexible Epoxy Resin System

- Polyurethane Series Insulating Adhesive

- PU insulating glue

- Special filler

- Auxiliary materials

- Application

- Case

- News

- Contact Us

Web Menu

- Home

- About Us

- Products

- Xrun Epoxy Resin Additives and Auxiliary Materials

- Epoxy insulating glue

- Epoxy Resin Systems For HV Products

- Epoxy Systems for Dry-Type Transformers

- Epoxy Resin System for MV & HV Insulation Parts with APG Process

- Flame-Retardant Epoxy Resin Systems

- Epoxy Resin Systems for Electric Insulation of High Thermal Conductivity

- Epoxy Resin Systems Curing at Ambient Temperature

- Epoxy Resin Systems for Outdoor Electrical Insulation

- Epoxy Resin Systems for Electric Composite

- Epoxy Systems for CT/VT

- Flexible Epoxy Resin System

- Polyurethane Series Insulating Adhesive

- PU insulating glue

- Special filler

- Auxiliary materials

- Application

- Case

- News

- Contact Us

Product Search

Language

Exit Menu

Epoxy Systems for Dry-Type Transformers

- Xrun Epoxy Resin Additives and Auxiliary Materials

- Epoxy insulating glue

- Epoxy Resin Systems For HV Products

- Epoxy Systems for Dry-Type Transformers

- Epoxy Resin System for MV & HV Insulation Parts with APG Process

- Flame-Retardant Epoxy Resin Systems

- Epoxy Resin Systems for Electric Insulation of High Thermal Conductivity

- Epoxy Systems for CT/VT

- Epoxy Resin Systems Curing at Ambient Temperature

- Epoxy Resin Systems for Outdoor Electrical Insulation

- Epoxy Resin Systems for Electric Composite

- Flexible Epoxy Resin System

- Polyurethane Series Insulating Adhesive

- Epoxy Resin Systems For HV Products

- PU insulating glue

- Special filler

- - Xrun Epoxy Resin Additives and Auxiliary Materials

- - Epoxy insulating glue

- - Epoxy Resin Systems For HV Products

- - Epoxy Systems for Dry-Type Transformers

- - Epoxy Resin System for MV & HV Insulation Parts with APG Process

- - Flame-Retardant Epoxy Resin Systems

- - Epoxy Resin Systems for Electric Insulation of High Thermal Conductivity

- - Epoxy Systems for CT/VT

- - Epoxy Resin Systems Curing at Ambient Temperature

- - Epoxy Resin Systems for Outdoor Electrical Insulation

- - Epoxy Resin Systems for Electric Composite

- - Flexible Epoxy Resin System

- - Polyurethane Series Insulating Adhesive

- - PU insulating glue

- - Special filler

Form of matter

- Solid state

- Liquid state

- Adjustable Formula

Glass transition temperature

- 50-60℃

- 60-70℃

- 70-80℃

- 80-90℃

- 90-100℃

- 100-110℃

- 110-120℃

- 120-130℃

- 130-140℃

- 140-150℃

- 150-160℃

- 160-170℃

- 170-180℃

- 180-190℃

Craft

- APG

- Vacuum casting

- Potting

- Coating

- Casting

- Impregnation

Application

- Indoor and outdoor switches

- Transformers

- Mutual inductors

- Electric reactor

- Insulating tie rods

- Curing at room temperature

- High toughness, non-toxic and flame-retardant

- Electrical components

- For outdoor electrical insulation

Classification

- - Xrun Epoxy Resin Additives and Auxiliary Materials

- Epoxy insulating glue

- --Epoxy Resin Systems For HV Products

- --Epoxy Systems for Dry-Type Transformers

- --Epoxy Resin System for MV & HV Insulation Parts with APG Process

- --Flame-Retardant Epoxy Resin Systems

- --Epoxy Resin Systems for Electric Insulation of High Thermal Conductivity

- --Epoxy Systems for CT/VT

- --Epoxy Resin Systems Curing at Ambient Temperature

- --Epoxy Resin Systems for Outdoor Electrical Insulation

- --Epoxy Resin Systems for Electric Composite

- --Flexible Epoxy Resin System

- --Polyurethane Series Insulating Adhesive

- PU insulating glue

- Special filler

Characteristics

- Ultra-High Viscosity

- Good adhesion

- Good insulation

- Low water absorption

- UItra-Low-Temperature Resistance

- Low-Temperature Resistance

- Good electromechanical properties

- Low partial discharge

- Low viscosity

- Flame- retardant

- High crack resistance

- Room temperature curing

- Smooth surface

- Low temperature rise

- High TG

- Long usable time

- UV resistance

- Fithy resistance

- Goog processability

- High thermal conductivity

- Interfacial conductivity

- Environmentally friendly

- Safe

- Flexible

- Low stress

- Crack-resistant

- Resistant to thermal shock

- Flame retardant

- Low density

- No sagging

-

- - Xrun Epoxy Resin Additives and Auxiliary Materials

- Epoxy insulating glue

- Epoxy Resin Systems For HV Products

- Epoxy Systems for Dry-Type Transformers

- Epoxy Resin System for MV & HV Insulation Parts with APG Process

- Flame-Retardant Epoxy Resin Systems

- Epoxy Resin Systems for Electric Insulation of High Thermal Conductivity

- Epoxy Systems for CT/VT

- Epoxy Resin Systems Curing at Ambient Temperature

- Epoxy Resin Systems for Outdoor Electrical Insulation

- Epoxy Resin Systems for Electric Composite

- Flexible Epoxy Resin System

- Polyurethane Series Insulating Adhesive

- PU insulating glue

- Special filler

-

- Ultra-High Viscosity

- Good adhesion

- Good insulation

- Low water absorption

- UItra-Low-Temperature Resistance

- Low-Temperature Resistance

- Good electromechanical properties

- Low partial discharge

- Low viscosity

- Flame- retardant

- High crack resistance

- Room temperature curing

- Smooth surface

- Low temperature rise

- High TG

- Long usable time

- UV resistance

- Fithy resistance

- Goog processability

- High thermal conductivity

- Interfacial conductivity

- Environmentally friendly

- Safe

- Flexible

- Low stress

- Crack-resistant

- Resistant to thermal shock

- Flame retardant

- Low density

- No sagging

-

-

HW-7042A CE2/E1 Certified Prefilled Epoxy Resin

HW-7042A CE2/E1 Certified Prefilled Epoxy ResinFeatures Pre-filled, can meet CE2/E1 requirements

-

HW-3906A Thermally Conductive Anti-Cracking Epoxy Resin

HW-3906A Thermally Conductive Anti-Cracking Epoxy ResinCharacteristics Thermal conductivity 1.0W/m.K, excell...

-

HW-8369-1A H-Grade High-Tg Prefilled Epoxy Resin

HW-8369-1A H-Grade High-Tg Prefilled Epoxy ResinFeatures Pre-filled, excellent reliability, H grade ...

-

HW-2867A F-Grade Prefilled Anti-Cracking Epoxy Resin

HW-2867A F-Grade Prefilled Anti-Cracking Epoxy ResinCharacteristic properties Pre-filled, excellent crack...

-

HE-8523 Low-Viscosity Adjustable Epoxy Resin

HE-8523 Low-Viscosity Adjustable Epoxy ResinCharacteristics Low viscosity, adjustable to meet per...

-

HE-8522 General-Purpose Adjustable Formula Epoxy Resin

HE-8522 General-Purpose Adjustable Formula Epoxy ResinCharacteristics General purpose, adjustable formula t...

-

HE-8272 F-Grade Excellent Anti-Cracking Epoxy Resin

HE-8272 F-Grade Excellent Anti-Cracking Epoxy ResinCharacteristic properties Pre-filled, excellent crack...

-

HW-8271A Prefilled Anti-Cracking Epoxy Resin

HW-8271A Prefilled Anti-Cracking Epoxy ResinCharacteristic properties Pre-filled, excellent crack...

-

HE-8271 H-Grade Anti-Cracking Low-Temperature Curing Epoxy Resin

HE-8271 H-Grade Anti-Cracking Low-Temperature Curing Epoxy ResinCharacteristics Excellent crack resistance, H grade ...

-

HE-827 H-Grade Anti-Cracking Epoxy Resin

HE-827 H-Grade Anti-Cracking Epoxy ResinCharacteristics Excellent crack resistance, H grade ...

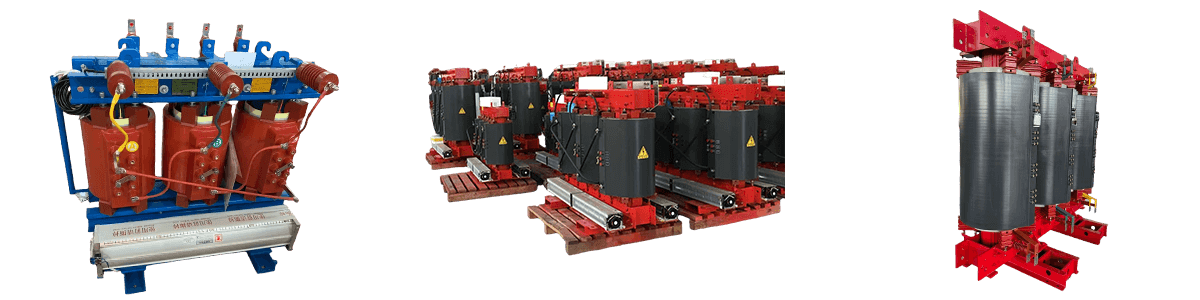

Epoxy Systems for Dry-Type Transformers

Dry-type transformers are manufactured by embedding coils and metal conductors in epoxy resin. The epoxy material offers excellent electromechanical properties and chemical resistance, but it is characterized by high modulus and brittleness. Additionally, the significant difference in thermal expansion coefficients between the epoxy polymer and the metal coils/conductors poses challenges. During the thermal curing process, factors such as curing shrinkage, high process temperature, ambient temperature fluctuations, and high-temperature rise under electrical loads can lead to multidimensional coupled internal stresses. This, combined with stress-induced degradation of the insulation due to mechanical, electrical, and thermal effects, introduces reliability risks to the product. The quality and performance of epoxy resin are critical, as they directly determine the reliability of cast-resin transformer products.

XRUN's epoxy resins for dry-type transformers are classified as follows:

● By Thermal Class: F-grade and H-grade.

● By Supply Form: Epoxy resin formulations (ready for filler addition).

● Pre-filled epoxy resin compounds (pre-mixed with fillers).

● By Operating Temperature: Standard type (for general environments).

● Ultra-low-temperature resistant type (for extreme cold conditions).

● By Thermal Conductivity: Standard type, High-thermal-conductivity type.

● By Flame Retardancy: Standard type. Flame-retardant type.

| Formulate | Tg(℃) | Feature |

| HE-827/HH-827/X106=100/100/200 | >60 | Ultra-Low Temperature(-65℃), H Class |

| HE-8271/HH-8271/X106=100/100/200 | >70 | Low Temperature(-40℃), H Class |

| HE-8272/HH-8272/X106=100/100/200 | >80 | Low Temperature(-40℃), Fclass |

| HE-8380A/HE-8380B/X106=100/100/200 | >80 | Ultra-Low Temperature(-65℃), H Class |

| HE-8522/HH-8522/HF-640/HA-6750/X106=100/100/0-20/0-1/200-300 | Be tailored | Be Tailored, H Class |

| HE-8523/HH-8523/HF-641/HA-6750/X106=100/85/0-20/0-1/200-300 | Be tailored | Be Tailored, H Class |

| HW-2867A/HW-2867B=100/100 | >70 | Prefilled, Ultra-Low Temperature(-65℃), H Class |

| HW-3906A/HW-3906B=100/100 | >80 | Prefilled, Low Temperature(-40℃), H Class |

| HW-7042A/HW-7042B=100/100 | >55 | Prefilled, Halogen-Free Flame Retradant |

| HW-8369-1A/HW-8369-1B=100/100 | >110 | Prefiiled, Ultra-Low Temprature(-65℃), H Class |

| S2245A/S2245B=100/100 | >75 | Low Temperature、H Class |

| S2145A/S2145B/SF1250=100/100/200 | >80 | Ultra-Low Temprature(-65℃), H Class |

-

2025-09-11

Founded on Sept.9th,1999, Xrun is a professional company of electrical insulation materials. With the advantage of speciality, Xrun focuses on R&D...

-

2025-09-11

The project "Epoxy Nanocomposites for Ultra-High Voltage Electrical Equipment and Key Application Technologies" is a national key research and develop...

-

2025-09-11

Our company has successfully developed a new type of high-toughness, non-toxic, and flame-retardant epoxy resin material. After third-party testing, t...

“ From this year “

Contact

Tel: +86-21-54943138

Phone:

Sales Ricky:+86-136 1183 0385

Sales Jason:+86-186 1635 6961E-mail: [email protected]

[email protected]

[email protected]

English

English